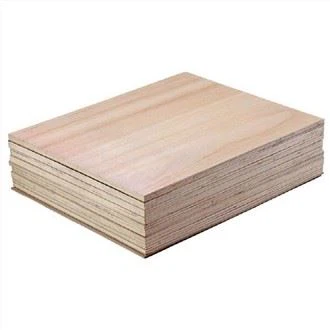

Pencil Cedar Plywood

Pencil cedar plywood is a commercial plywood with grooved lining.

Product Introduction

BB/CC Grade Pencil cedar commercial plywood

SUPPLY WITH THE HIGHEST COST-PERFORMANCE RATIO

Pencil cedar plywood is a commercial plywood with grooved lining. In simple terms, commercial plywood is the basic or standard plywood available. Moisture-proof, plywood can withstand a certain amount of moisture, humidity and humidity. It can also be cut into small pieces and reused. It is commonly used as a household flooring material and is also suitable for many shipbuilding applications, including masts, spars and interior decoration.

Product Features

Pencil cedar plywood is not only resistant to wear, cracking, acid and alkali, but also has no color pollution between the concrete and the formwork. Pencil cedar veneer is usually a peel-cut whole piece of veneer, and no flat piece is used for fancy plywood. Pencil cedar is a high-quality hardwood. Because of its easy processing, uniform color, fine texture and surface treatment characteristics, it is used for high-end cabinets and custom furniture. Wood is suitable for machines and hand tools, has excellent molding properties, and produces smooth, high-grade surfaces.

|  |

DESCRIPTION DETAIL

PRODUCT NAME | COMMERCIAL PLYWOOD---COST-EFFECTIVE PENCIL CEDAR PLYWOOD | |

CORE MATERIAL | 100% POPLAR, 100% EUCALYPTUS OR COMBI CORE | |

GRADE | BB/BB, BB/CC | |

GLUE TYPE | MR /E0/E1/CARB P2(EPA) / WBP GLUE | |

SIZE | THICKNESS | 2.5MM/3.6MM/5.2MM/9MM/12MM/15MM/18MM OR AS REQUEST |

WIDTH*LENGTH | 1220X2440MM, 1250X2500MM , 1500X3000MM OR AS REQUEST | |

MOISTURE | 8-16% | |

APPLICATION | INTERIOR DECORATION, PACKING , FURNITURE, BASE PALTE | |

PATMENT TERMS | 30%TT IN ADVANCE AND THE BALANCE AGAINST COPY OF BILL, OR LC AT SIGHT | |

SUPPLY CAPACITY | 50000 CBM PER MONTH | |

MOQ | 20FT CONAITNER | |

DELIVERY TIME | 15-20 DAYS AFTER DOWN PAYMENT | |

PRODUCTION PROCESS

QUALITY CONTROL & PACKING