Birch Plywood

SOURCES: THE BALTIC BIRCH TREE ORIGINATES IN THE BALTIC STATES – ESTONIA, LATVIA AND LITHUANIA. BALTIC BIRCH PLYWOOD IS PRIMARILY PRODUCED IN FINLAND AND RUSSIA.

BOTANICAL NAME: BETULA SPP.

COMMON NAMES: BALTIC BIRCH, RUSSIAN BIRCH

SOURCES: THE BALTIC BIRCH TREE ORIGINATES IN THE BALTIC STATES – ESTONIA, LATVIA AND LITHUANIA. BALTIC BIRCH PLYWOOD IS PRIMARILY PRODUCED IN FINLAND AND RUSSIA.

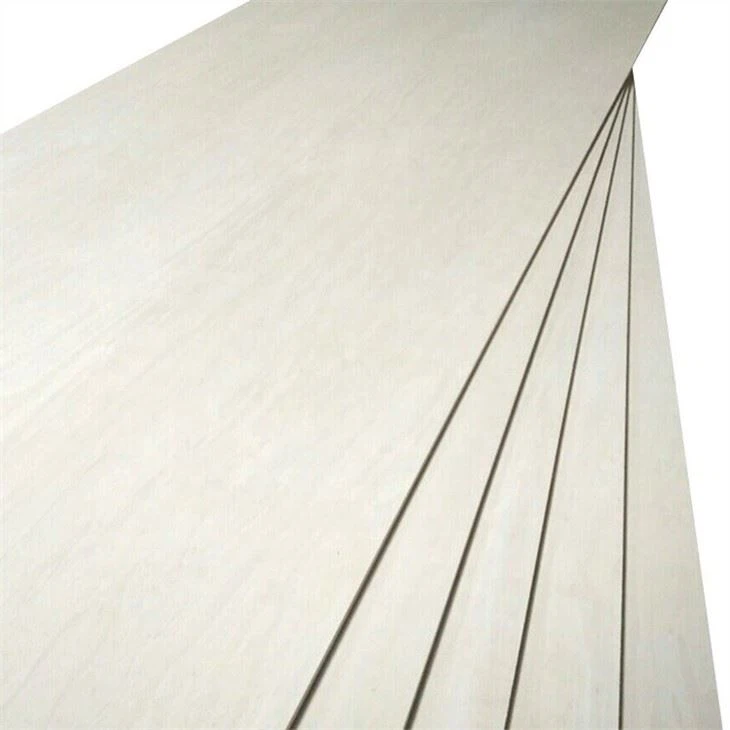

APPEARANCE: VALUED FOR ITS APPEALING LIGHT COLOR, BALTIC BIRCH PLYWOOD FEATURES A UNIFORM GRAIN, SMOOTH TEXTURE AND OUTSTANDING DURABILITY.

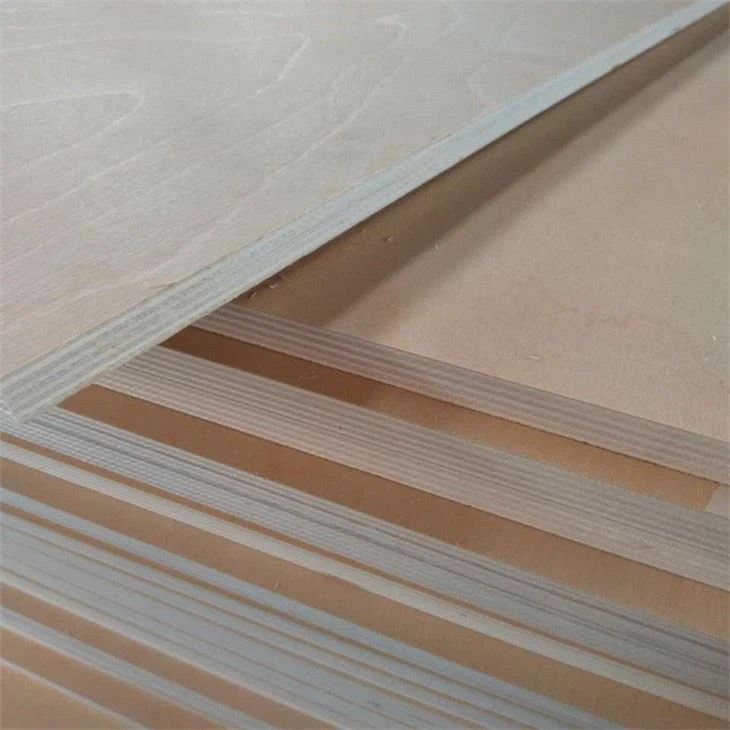

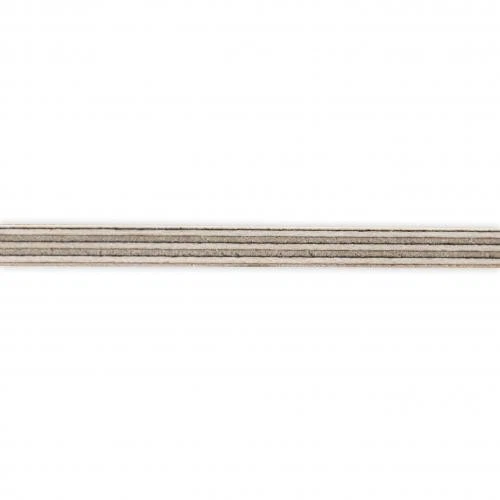

PHYSICAL PROPERTIES: BALTIC BIRCH VARIES IN THICKNESS AND CONTAINS AN ODD NUMBER OF PLIES. THE TWO OUTER PLIES, WHICH COMPRISE THE FRONT AND BACK, SHOW VERTICAL WOOD GRAIN THAT RUNS LENGTHWISE THROUGHOUT THE SHEETS. INNER PLIES HAVE ALTERNATING HORIZONTAL OR VERTICAL GRAIN, WHICH PROVIDES INCREASED STRENGTH AND RESISTANCE TO WARPING OR MOISTURE DAMAGE.

WORKING PROPERTIES: WHILE MOST PLYWOOD TENDS TO BE PAINTED, BALTIC BIRCH IS ATTRACTIVE ENOUGH TO STAND ALONE WITH LIGHT SANDING, VARNISHING OR STAINING.

USES: BECAUSE OF ITS PLEASING APPEARANCE, IT IS A WOOD TYPICALLY USED FOR CABINETRY AND OTHER FURNITURE. BALTIC BIRCH IS SUITABLE FOR A VARIETY OF PROJECTS, FROM CABINETMAKING TO BUILDING CONSTRUCTION.

DESCRIPTION DETAIL

PRODUCT NAME | BIRCH PLYWOOD | |

RAW MATERIAL | BIRCH, POPLAR, PINE,HARDWOOD OR MIXED | |

GLUE TYPE | E2,E1,E0,CARB P2 | |

SIZE | THICKNESS | 1.0MM/1.9MM/2.5MM/6MM/9MM/12MM/15MM/18MM OR AS REQUEST |

WIDTH*LENGTH | 1220X2440MM, 1250X2500MM , 1500X3000MM OR AS REQUEST | |

MOISTURE | 8-12% | |

APPLICATION | PACKING , | |

PATMENT TERMS | 30%TT IN ADVANCE AND THE BALANCE AGAINST COPY OF BILL, OR LC AT SIGHT | |

SUPPLY CAPACITY | 100000 CBM PER MONTH | |

MOQ | 20FT CONAITNER | |

DELIVERY TIME | 15-20 DAYS AFTER DOWN PAYMENT | |

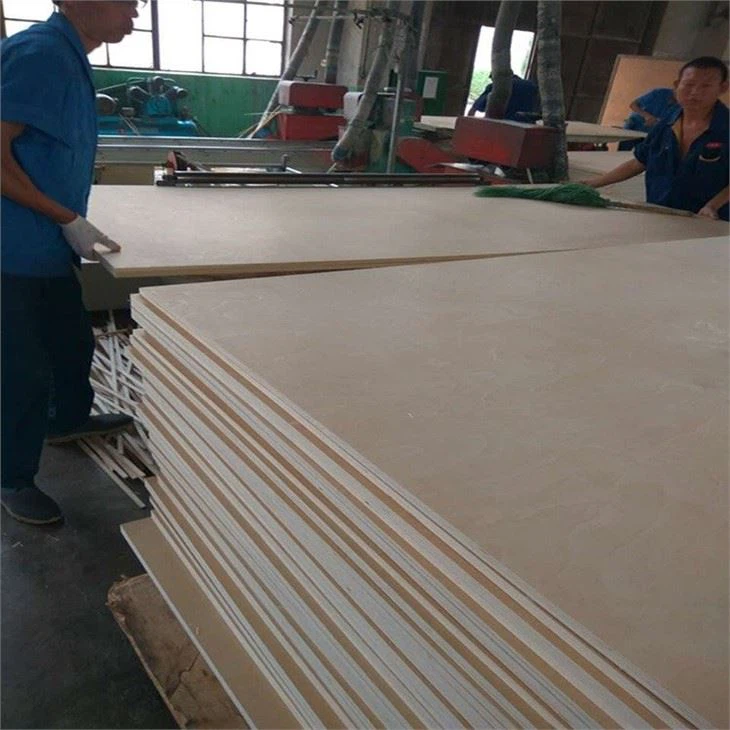

PRODUCTION PROCESS

QUALITY CONTROL & PACKING

We have persistent pre-shipping inspection system. The inspection process starts immediately after order is confirmed. The grade and type of raw material, processing methods inspection and packing details will be advised to the factory management.

Our factory and certificate

After 20 years of development, SUMEC has become a professional enterprise providing modern service in building material industry. SUMEC has invested our own wood panel manufacturing bases successively and obtained successively a variety of business qualifications including ISO9001\14001\18001 and product certifications such as FSC and CARB. We now have an annual production capacity of over 500 thousands cubic meters and can meet various demands.