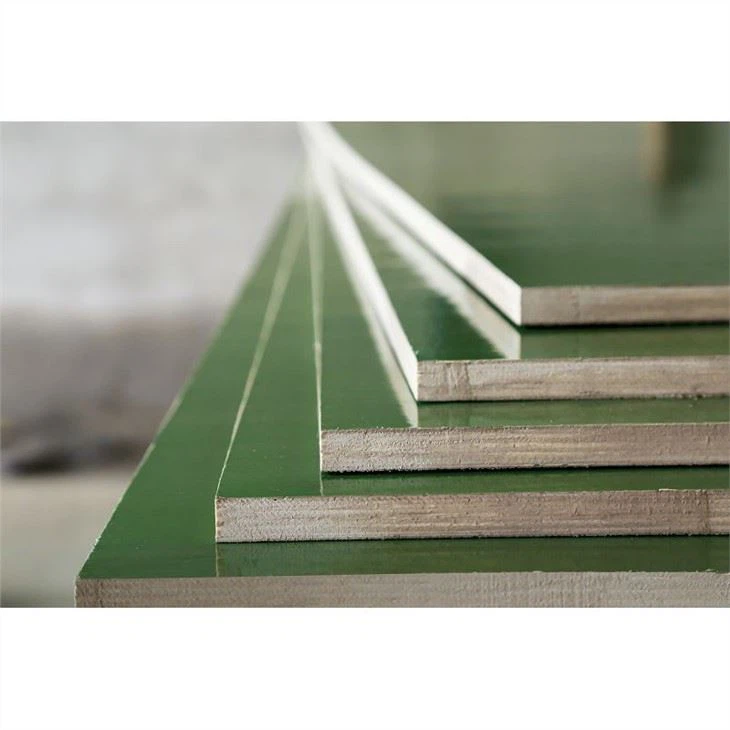

Durable Water Proof Plastic Film Faced Plywood

Durable Waterproof Plastic Film-Faced Plywood is a new type of film-facing laminate.

Product Introduction

DURABLE PP PLASTIC FILM FACED PLYWOOD FOR CONSTRUCTION FRAMEWORK, BUILD A BETTER LIFE

Durable Waterproof Plastic Film Faced Plywood is a new type of film-facing laminate. Its base material is particle board and medium fiber board, which are made by bonding the base material and the surface. The surface veneers are mainly domestic and imported, because they are fireproof, abrasion-resistant, and waterproof. In the production of all poplar plywood, each sheet is selected and repaired and used after secondary molding.

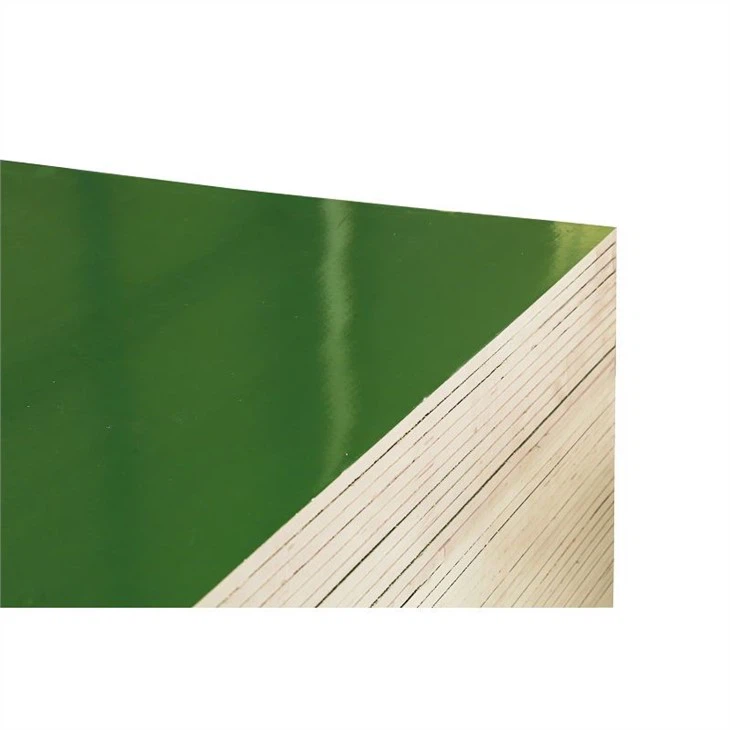

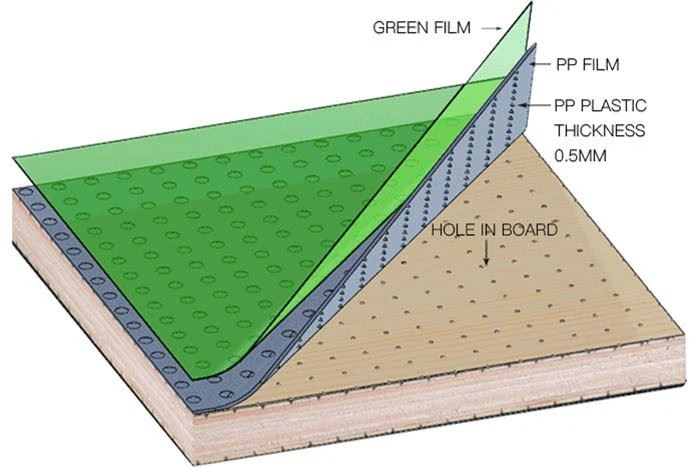

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer.

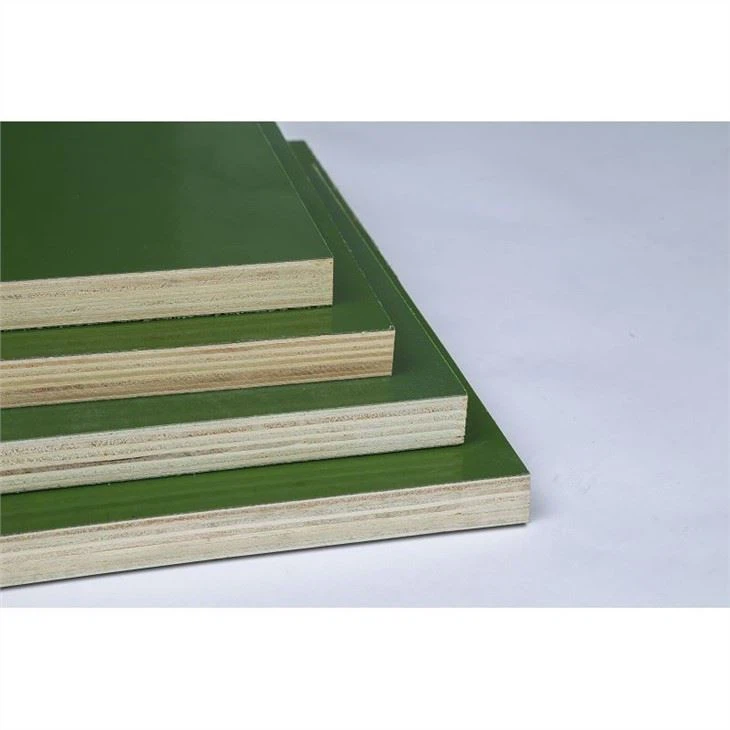

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer. It is easy to demould, does not contain a release agent, does not stick to cement, and the concrete surface is very smooth. It has more reuse times than ordinary laminated plywood. It has perfect waterproof performance and wear resistance. Glue makes it stronger and increases the reuse time to 20-30 times. Durable Water Proof Plastic Film Faced Plywood is easy to transfer to the concrete build. It is waterproof, wear-resistant, crack-resistant and environmentally friendly. It is sealed with waterproof paint, and the color can be customized. It is used in real estate construction and formwork panels. It has stronger impact strength and high processability.

Product Features

The advantages of durable waterproof plastic film-faced plywood are also obvious, such as good bonding strength, no glue, no break, waterproof, anti-corrosion, etc. When in use, the surface should be relatively smooth, with good flatness, and no carbonization, and the overall thickness of the board should be relatively uniform. Since waterproof glue and phenolic glue are used for bonding in production, the bonding strength is very high and can be greatly adapted to different usage scenarios.

DESCRIPTION DETAIL

PRODUCT NAME | PP PLASTIC FILM-FACED PLYWOOD / GREEN PP PLYWOOD | |

CORE MATERIAL | 100% POPLAR, 100% EUCALYPTUS OR COMBI CORE | |

TIMES OF HOT PRESS | TWO TIMES, THREE TIMES | |

GLUE TYPE | MR/ WBP MELAMINE GLUE/PEHNOLIC GLUE | |

FILM | GREEN | |

SIZE | THICKNESS | 12MM/15MM/18MM/21MM OR AS REQUEST |

WIDTH*LENGTH | 1220X2440MM, 1250X2500MM , OR AS REQUEST | |

MOISTURE | 8-12% | |

APPLICATION | CONCRETE, FORMWORK | |

PAYMENT TERMS | 30%TT IN ADVANCE AND THE BALANCE AGAINST A COPY OF THE BILL, OR LC AT SIGHT | |

SUPPLY CAPACITY | 100000 CBM PER MONTH | |

MOQ | 20FT CONTAINER | |

DELIVERY TIME | 15-20 DAYS AFTER DOWN PAYMENT | |

PRODUCTION PROCESS

1. RAW MATERIAL ---2. GLUING &LAY UP – 3. COLD & HOT PRESS --- 4. PUTTING – 5. SANDING –6. VENEER LAMINATION --- 7. POLISHING --- 8. INSPECTION – 9. LOADING & SHIPPING

QUALITY CONTROL & PACKING

We have a persistent pre-shipping inspection system. The inspection process starts immediately after the order is confirmed. The grade and type of raw material, processing methods, inspection and packing details will be advised to the factory management.

Our factory and certificate

After 20 years of development, SUMEC has become a professional enterprise providing modern service in the building material industry. SUMEC has invested our own wood panel manufacturing bases successively and obtained successively a variety of business qualifications including ISO 9001, 14001, 18001 and product certifications such as FSC and CARB. We now have an annual production capacity of over 500 thousand cubic meters and can meet various demands.