EIR SPC Flooring

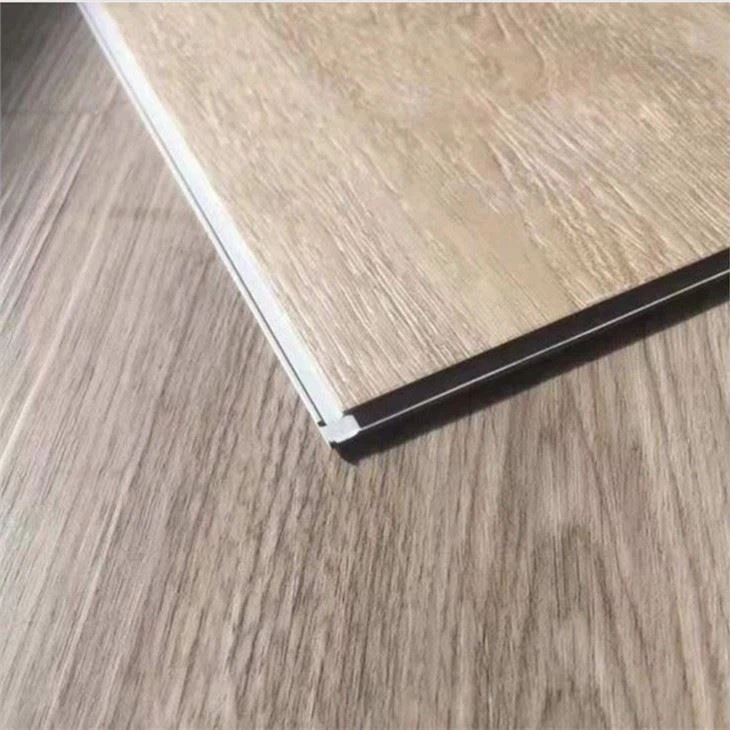

EIR SPC Flooring has similar structure with non-EIR SPC Flooring. The biggest difference is that the wood grain of EIR(emboss in register) SPC Flooring is much more vivid, lifelike, and close to real wood.

Product Overview

EIR SPC Flooring has similar structure with non-EIR SPC Flooring. The biggest difference is that the wood grain of EIR(emboss in register) SPC Flooring is much more vivid, lifelike, and close to real wood.

Traditional rigid core SPC Flooring is extruded, and then embossed with a large and heavy steel roller.

The pattern is already embossed on the steel roller. There are hundreds of floor color designs, while only 2-3 ordinary embossment designs. Thus the wood grain of color film does not match the embossment.

On the contrary, EIR SPC Flooring has the embossment matched to the wood grain.

What you need to do is to customise a steel roller. This roller will emboss excatly on your wood grain, and avoid other arear of the color film; 1 roller, 1 wood grain. Then, the wood grain will be more vivid, lifelike and close to real wood.

Product Parameters

Product Name: | EIR SPC Flooring |

|

| Advantages: | Emboss In Register; Extremely Lifelike Wood Grain; | |

Width: | 6/7/9/12inch; 150/180/230/310mm | |

| Length: | 38/48/60/72inch; 970/1220/1530/1830mm | |

Thickness: | 3.5-6.5mm | |

| Wear Layer: | 0.3/0.5mm, 12/20mil | |

| Acoustic Pad: | 1.0/1.5/2.0mm IXPE/EVA | |

| Bevel: | V Groove Bevel; Micro Bevel; Painted Bevel |

|

Phthalate: | NO | |

| Heavy Metal: | NO | |

Lifetime: | 15 years at home 8 years at commercial | |

| PS: | Need to customise embossing ro- ller according to the wood grain |

Technical Data

Test Items | Test Standards | Test Results |

Residual Indentation | 0.15<Is≤0.40 | 0.16 |

Flammability | B1 | |

Peel Strength | N/50mm | (average)≥75 |

| (minimum)≥70 | ||

| Click Strength | KN/m | ≥1.5 |

Size Change Rate After-heating | Longitudinal≤0.25% | Length: -0.10 |

| Horizontal≤0.25% | Width: -0.07 | |

Size Change Rate After Heating | Average∆E* | 0.09 |

Formaldehyde Emission | ≤0.124 mg/m³ | 72h Not Detected |

Total Volatile Limit | ≤10 g/m³ | 4.9 |

| Phthalic Plasticiser | ≤0.1% | Not Detected |

Colour Designs

800+ Wood Grain Design in SUMEC Collection: http://sumec.menu.zboec.com/

Packing & Shipping

| Inspection: | inspection on raw material, during process, after production |

| Packaging: | in cartons and wooden pallets; wrapping film; air bag for crash protection |

| Transport: | shipping from Port of Shanghai |

| Trade Term: | FOB, CIF, CFR, FCA |

Payment Method: | T/T, L/C |

Other Products

FAQ

Q: How different is EIR SPC Flooring, from Non-EIR SPC Flooring?

A: It's easy to find the different visually, especially when the room is well-lit and the wood grain is comparetively complex. You can find that the EIR wood grain and burl is deeper, just like real trees.

Q: Is their Extra Cost of EIR SPC Flooring?

A: The price per square meter is same as non-EIR, but you need to customise a roller, with embossment extremely the same as the wood pattern in the color design. The cost is about 10,000 USD.

Q: How long is the lead time of roller?

A: About 30 days.

Q: How long is the lead time of floorings?

A: Normally, 25-35 days, after receiving the deposite.

Q: What is your destination market?

A: Most of our products are exported, thus we always keep a strict standard on quality. Our main markets include US, Canada, UK, Chile, Argentina, etc.

Q: Where is your factory?

A: Our factory is in Wuxi, a modern large city in Jiangsu Province; 50km west to Suzhou, 100km west to Shanghai.

Q: What is the M.O.Q? Can I buy 100sqm?

A: Usually the M.O.Q is 1000 square metres per size per color.