Bus Vinyl Flooring

Bus Vinyl Flooring is the most popular choice of city bus, shuttle bus, school bus, coach, metro. In these vehicles, emergency brakes could happen from time to time. Some passengers even to stand and try to stay balance difficultly. This increases the risk of falling over and ingury. As for manufacturers and operators, safety is the first priority.

Product Overview

Bus Vinyl Flooring is the most popular choice of city bus, shuttle bus, school bus, coach, metro. In these vehicles, emergency brakes could happen from time to time. Some passgengers even to stand and try to stay balance difficultly. This increases the risk of falling over and ingury. As for manufacturers and operators, safety is the first priority.

Under this circumstance, bus vinyl flooring is necessary. It has special embossment, and is embedded with emery granules. These increase the friction coefficient between shoes and floor. Passgener will get more stability, even in rainy and snowy weathers (which cause wet floor). Secondly, the flooring has dark colours and puzzle patterns. This can conceal most stain and dirt. Drivers do not need to frequently clean. Also, the flooring is easy to clean. Flush, mop, dry, and that's all. The flooring is 100% watrertight.

Product Parameters

Product Name: | Safety Bus Flooring Sheet |

|

| Selling Points: | Excellent Anti-slip Performance; Stain Concealment; | |

Sheet Width: | 2m | |

| Sheet Length: | 20m | |

Thickness: | 2.0mm | |

Weight: | 2600g/m2 | |

Anti-slip Performance: | R10, R11 (DIN51130) | |

| Warranty: | 15 years |

|

| Heavy Metal: | NO | |

| Phthalate: | NO | |

| Glass Fibre: | YES | |

Surface: | UV coating (optional) | |

| Footing: | Semi-rigid | |

| Installation: | Applying Glue |

Qualified Technical Data

The flooring has passed the VOCs test with qualified data. We have striction requirement on raw materials. People's safety and health are what we cherish most.

Test Items | Test Standards | Test Results |

Fire Classificatioin | GB/T8624 | Grade B1 |

Anti-slip Performance | DIN 51130 | R10, R11 |

Wear Resistance | EN 660-2 | Group T |

| Residual Indentation | ISO 24343-1 | ≤0.1mm |

Colour Fastness | ISO 105-BO2 | ≥6 Grade |

Chemical Resistance | ISO 26987 | Fine |

Dimensional Stability | ISO 23999 | ≤0.2% |

Roller Wear | ISO 4918 | 25000R |

| Limit of Harmful Substances | GB18586 | Qualified |

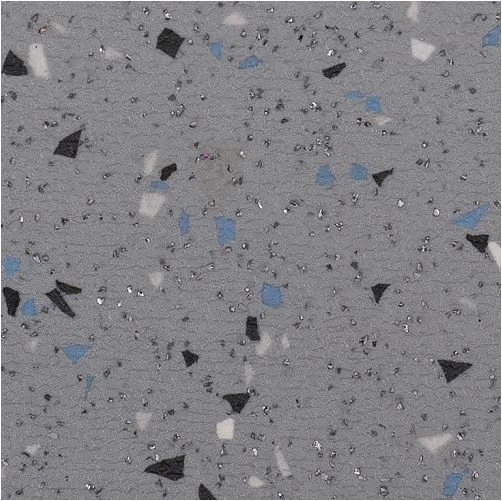

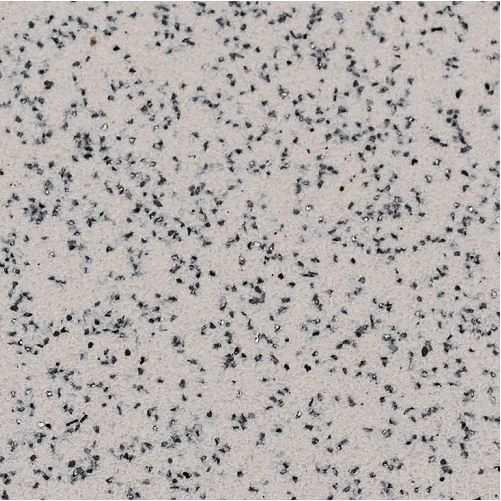

Colour Designs

All SUMEC Flooring Colour & Designs, Click Picture or Open: http://sumec.menu.zboec.com/

22 Safety Kitchen Flooring Colours At Your Call

Careful Packing & Fast Shipping

| Production: | laminating, embossing, UV coating |

| Inspection: | raw material inspection, in-progress inspection, pre-shipping inspection |

| Packaging: | wrapping paper packaging |

| Loading: | in pallet, air bag protection, belt fastening, 20 feet container |

| Transport: | corporation with 20+ shipping agents, |

Other Products

FAQ

Q: How to install safety bus flooring?

A: Surface agent; Adhesive; Capping Strip; Nails

Q: How to clean the safety bus flooring?

A: Mop or flush; it's 100% waterproof

Q: How long is the lead time?

A: Normally, 10-15 days after deposit.

Q: Can I buy 10-20 sqm? 100-200 sqm?

A: Sorry, we do not retail. MOQ is 1000 sqm per specification.

Q: Can I require some samples?

A: Of course. We can deliver to you, random colours what we have in storage.

Q: Can we have credit? How long?

A: Usually we suggest you using L/C. We seldom give credits, except long-term clients.