Acoustic Wall Panel

With wooden slats acoustic panel, the focus is on the design of the ceiling or wall at the same time as the acoustic features. The acoustic panels add one aesthetic dimension to the space, give the edge to the identity of the home and create a warm expression in the home. Acoustic absorption of the panels provides a comfortable indoor environment. The acoustic panels are made of 10o% polyester, MDF and wood veneer, whereby they get very beautiful expressions with varying markings. They are found in 10 different varieties and colors everything after which expression is desired.

Product Introduction

With wooden slats acoustic panel, the focus is on the design of the ceiling or wall at the same time as the acoustic features. The acoustic panels add one aesthetic dimension to the space, give the edge to the identity of the home and create a warm expression in the home. Acoustic absorption of the panels provides a comfortable indoor environment. The acoustic panels are made of 10o% polyester, MDF and wood veneer, whereby they get very beautiful expressions with varying markings. They are found in 10 different varieties and colors everything after which expression is desired.

Product Parameters:

Material | MDF and PET Felt |

MDF Thickness | 12mm |

Polyester Thickness | 9mm/12mm |

Finish | Melamine,Wood veneer |

Size | 2400*600*21mm/2800*600*21mm/Customized |

NRC | >0.85 |

Fire rating | SGS-ASTME84CLASSA,TUV-EN13501CLASSB |

Environmental protection level | E0 |

Use Range

Set up as a ceiling or wall acoustic panel can be set up as a ceiling or on a wall. The panels are installed in the existing fire-approved buildings, by spot glueing and fastening with screws. It is not recommended to set up the acoustic panels in rooms with high humidity.

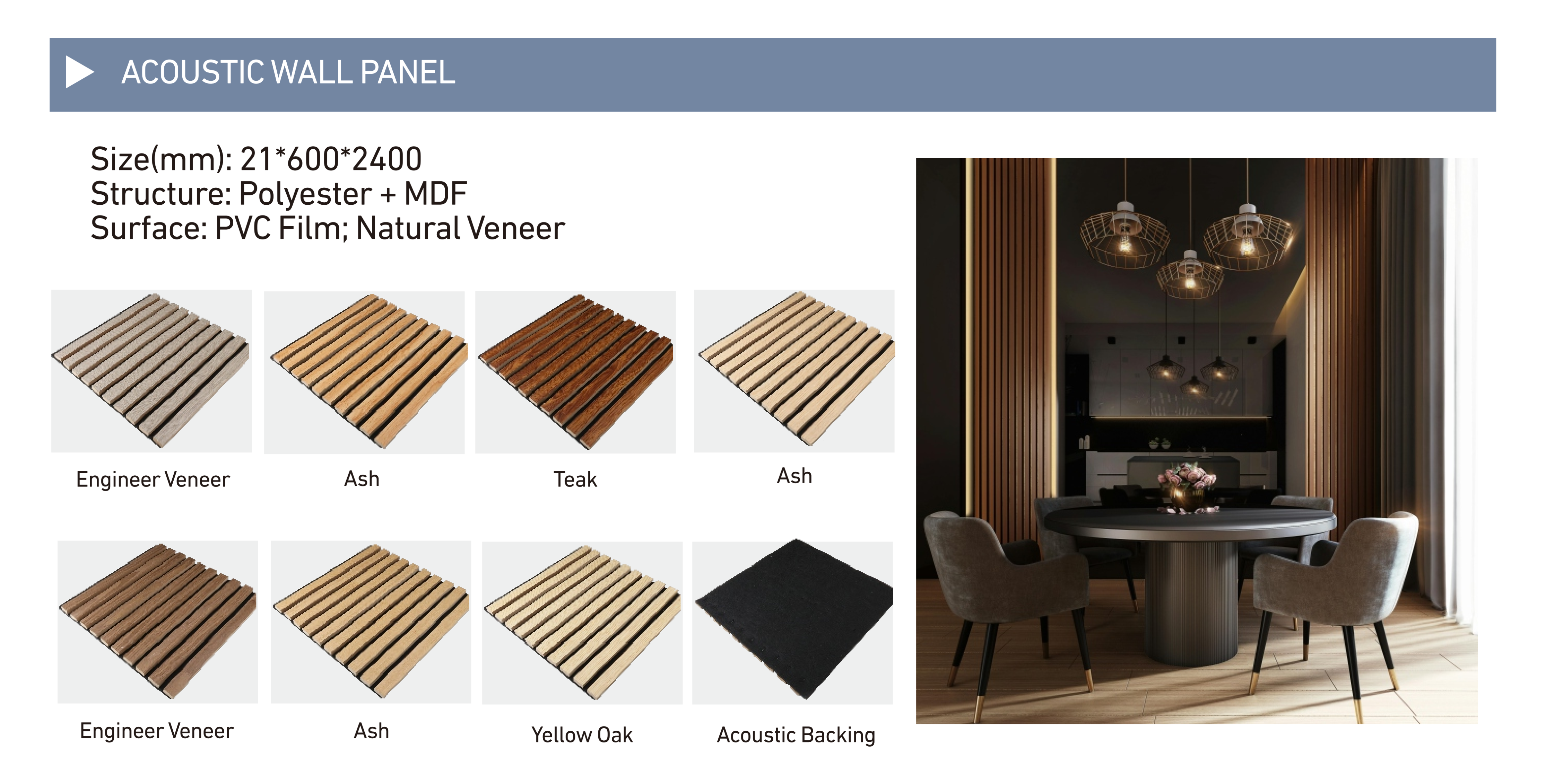

Variations of Wood Veneer

Be aware that there will be variations and differences in the veneer from production to production, which is why we do not recommend getting delivered to the same project over several rounds.

Care and Maintenance

We recommend adding a protective finish to the panels if possible. Something like oil is perfect as it protects and keeps the natural look and feel of the wood.

DESCRIPTION DETAIL

Size(mm):21*600*2400

Structure: Polyester + MDF

Surface: PVC Film; Natural Veneer

PRODUCTION PROCESS

1. RAW MATERIAL ---2. GLUING &LAY UP – 3. COLD & HOT PRESS --- 4. PUTTING – 5. SANDING –6. VENEER LAMINATION --- 7. POLISHING --- 8. INSPECTION – 9. LOADING & SHIPPING

QUALITY CONTROL & PACKING

We have a persistent pre-shipping inspection system. The inspection process starts immediately after the order is confirmed. The grade and type of raw material, processing methods, inspection and packing details will be advised to the factory management.

Our factory and certificate

After 20 years of development, SUMEC has become a professional enterprise providing modern service in the building material industry. SUMEC has invested our own wood panel manufacturing bases successively and obtained successively a variety of business qualifications including ISO 9001, 14001, 18001 and product certifications such as FSC and CARB. We now have an annual production capacity of over 500 thousand cubic meters and can meet various demands.