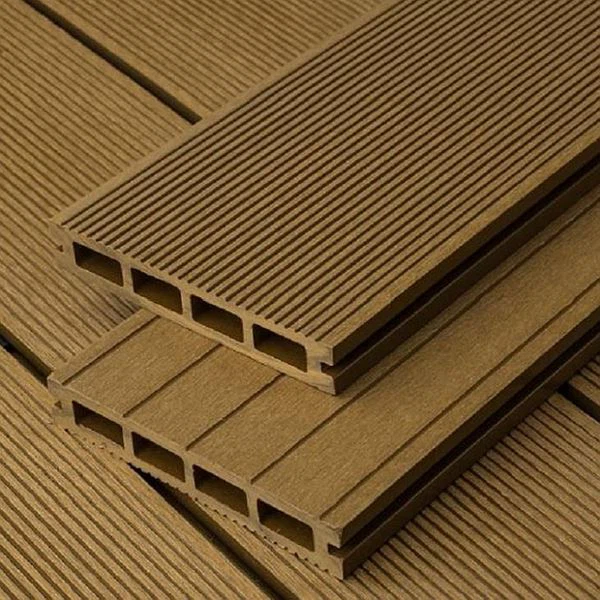

WPC Outdoor Flooring

WPC Decking is a composite(C) outdoor floor, usually used in backyard, balcony, garden, park, vacation resort, outdoor swimming pool, etc.. Main material is Wood Power(W) and Polyethylene(P). It is raised, and paved on beams. The installation is easy, fast and can be DIY by green hands. The life time is 25 years at home and 18 years at commercial, depending on conditions.

Product Overview

WPC Decking is a composite(C) outdoor floor, usually used in backyard, balcony, garden, park, vacation resort, outdoor swimming pool, etc.. Main material is Wood Power(W) and Polyethylene(P). It is raised, and paved on beams. The installation is easy, fast and can be DIY by green hands. The life time is 25 years at home and 18 years at commercial, depending on conditions.

Product Parameters

Product Name: | WPC Decking |

Advantages: | All-weather Resistant; Anti-bacteria, anti-mildew; |

Material: | Wood Powder; Polyethylene(PE); |

Width: | 100/110/115/120/135/140/145/ 150/160/200mm |

Thickness: | 12/16/20/22/25/30/40mm |

Cross Profile: | Solid; Half Solid; Round Hollow; Square Hollow |

Surface: | Sanding; Brushing; Wood Grain; 3D Vintage |

Color: | Antique; Teak; Redwood; Walnut; Light Gray; Silver Gray; Charcoal |

Category: | 1st Generation Class; 2nd Generation Co-extrusion; |

Formaldehyde: | NO |

Heavy Metal: | NO |

Lifetime: | 20 Years For Home 15 Years For Commercial |

Technical Data

Property | Test Methods | Values | |

Flexural Property | Load of Rupture | EN 15534-1 Annex A | ≧ 3300N |

Flexural Strength | EN 15534-1 7.3.2 | ≧ 20MPa | |

Flexural Modulus | EN 15534-1 7.3.2 | ≧ 2000MPa | |

Moisture Resistance-boiling Test | Swelling | ≤3% in thickness | |

EN 15534-1 8.3.3 | ≤0.5% in width | ||

≤0.3% in length | |||

EN 15534-1 8.3.3 | ≤5% in weight | ||

Linear Thermal Expansion Coefficient | EN 15534-1 9.2 | ≤5X10-5C-1 | |

Direct Screw Withdrawal | ASTM D1037-12 section 16 | ≧ 4000N | |

Shore Hardness | ASTM D2240-15 | ≧ D70 | |

Density | ASTM D792-13 Method A | ≧ 1.2G/cm3 | |

Packing & Shipping

Process: mixing and granulation; extrusion; surface processing; cutting & packing; finished

Inspection: inspection on raw material, during process, after production

Packaging: in wooden pallets; wrapping film;

Transport: shipping from Port of Nanjing/Shanghai

Trade Term: FOB, CIF, CFR, FCA

FAQ

Q: How long is the lead time?

A: Normally, 25-35 days, after receiving the deposite.

Q: What is your destination market?

A: Most of our products are exported, thus we always keep a strict standard on quality. Our main markets include US, Canada, UK, Chile, Argentina, etc.

Q: What is the M.O.Q? Can I buy 100sqm?

A: Usually the M.O.Q is 600 square metres per size per color.

PRODUCTION PROCESS

1. RAW MATERIAL ---2. GLUING &LAY UP – 3. COLD & HOT PRESS --- 4. PUTTING – 5. SANDING –6. VENEER LAMINATION --- 7. POLISHING --- 8. INSPECTION – 9. LOADING & SHIPPING

QUALITY CONTROL & PACKING

We have a persistent pre-shipping inspection system. The inspection process starts immediately after the order is confirmed. The grade and type of raw material, processing methods, inspection and packing details will be advised to the factory management.

Our factory and certificate

After 20 years of development, SUMEC has become a professional enterprise providing modern service in the building material industry. SUMEC has invested our own wood panel manufacturing bases successively and obtained successively a variety of business qualifications including ISO 9001, 14001, 18001 and product certifications such as FSC and CARB. We now have an annual production capacity of over 500 thousand cubic meters and can meet various demands.